.webp)

.webp)

_16-09-2025.webp)

LubeAdd® Soluble Cutting Oil Emulsifiers are specifically formulated to enhance the performance of soluble cutting oils used in machining and metalworking applications. This emulsifier creates stable emulsions, ensuring optimal lubrication and cooling during the cutting process. Designed to meet the rigorous demands of various machining operations.

Suitable for use with Group I and II base oils, allowing for versatile applications in various industrial environments.

With LubeAdd® Soluble Cutting Oil Emulsifiers, you can achieve superior performance, enhanced tool life, and improved productivity in your machining operations, ensuring efficient and reliable results across a variety of applications.

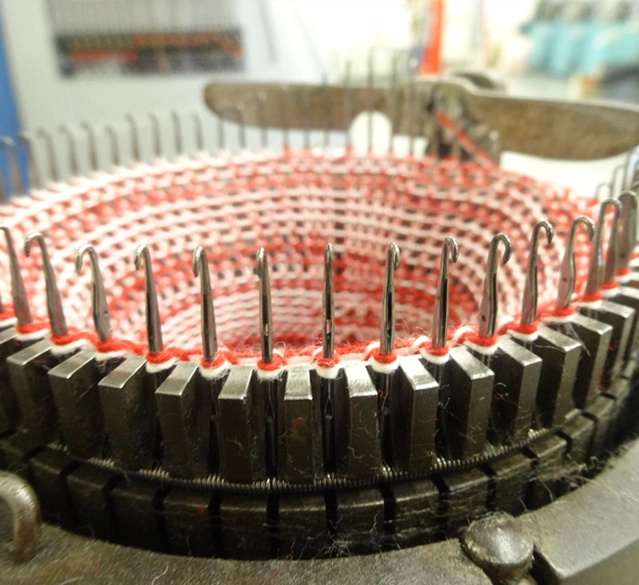

LubeAdd® Knitting Oil Additives are specialized solution designed to enhance the performance of lubricants used in textile machinery, particularly knitting machines. This additive ensures smooth operation, reduces wear, and protects machine components, even under high-speed and continuous operation conditions.

LubeAdd® Knitting Oil Additives is a premium solution designed for lubricants used in knitting machinery. It ensures smooth operation, reduces friction, and protects critical components like needles and sinkers from wear. With excellent detergency and high oxidation stability, it keeps machines clean, minimizes downtime, and ensures stain-free fabric production. Ideal for high-speed, continuous operations.

LubeAdd® Ashless Additive Packages are high-performance, metal-free solution engineered for industrial lubricants that demand exceptional cleanliness and long-lasting protection. Designed without metallic detergents, it ensures low-ash performance while delivering outstanding thermal and oxidative stability across a wide range of industrial applications.

LubeAdd® Hydraulic Oil Additives are high-performance solution engineered to enhance the protection and performance of hydraulic fluids across a wide range of industrial and mobile applications. Designed for use with Group I and Group II base oils, it ensures smooth operation, excellent system cleanliness, and extended fluid life.

LubeAdd® Hydraulic Oil Additives is ideal for formulating premium hydraulic oils that meet or exceed international performance standards.

LubeAdd® Rust Preventive Oil Additives are premium formulation designed to enhance the protective qualities of lubricants in various industrial applications. This additive can be easily blended into oils and greases, significantly improving their performance and protective capabilities.

With LubeAdd® Rust Preventive Oil Additives, you can enhance the protective qualities of your lubricants, ensuring optimal performance and reliability in your operations.

LubeAdd® Thermic and Quenching Oil Additives are specialized formulation designed specifically for heat transfer and quenching applications in various industrial settings. This additive optimizes thermal management, ensuring efficient cooling and heat dissipation during critical processes.

With LubeAdd® Thermic and Quenching Oil Additives, you can achieve optimal heat management and cooling efficiency, ensuring high-quality results in your industrial applications.

LubeAdd® Slideway Oil Additives are high-performance additive package designed to enhance the lubrication and performance of slideway and guideway oils. It provides exceptional friction control, stick-slip prevention, and wear protection, ensuring smooth and precise machine tool operation. This additive is ideal for both horizontal and vertical slideways, ensuring accurate positioning and extended equipment life.

LubeAdd® Slideway Oil Additives ensures smooth operation, precise movement, and long-lasting protection for industrial machinery, making it essential for high-precision machining applications.

LubeAdd® Compressor Oil Additives are high-performance additive package designed to improve the functionality and longevity of compressor oils. Tailored for rotary, screw, and reciprocating compressors, this additive provides outstanding anti-wear properties, oxidation resistance, and superior corrosion protection, ensuring smooth, reliable, and efficient compressor operation.

LubeAdd® Compressor Oil Additives is essential for enhancing the performance, efficiency, and lifespan of compressors, making it a reliable solution for demanding industrial and commercial applications.

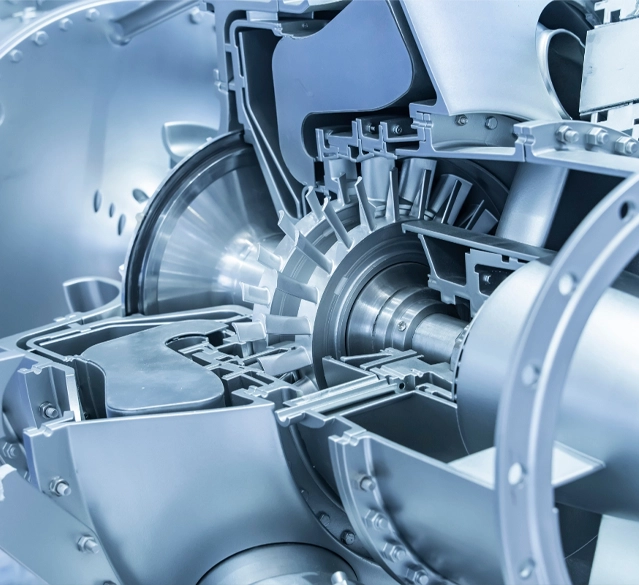

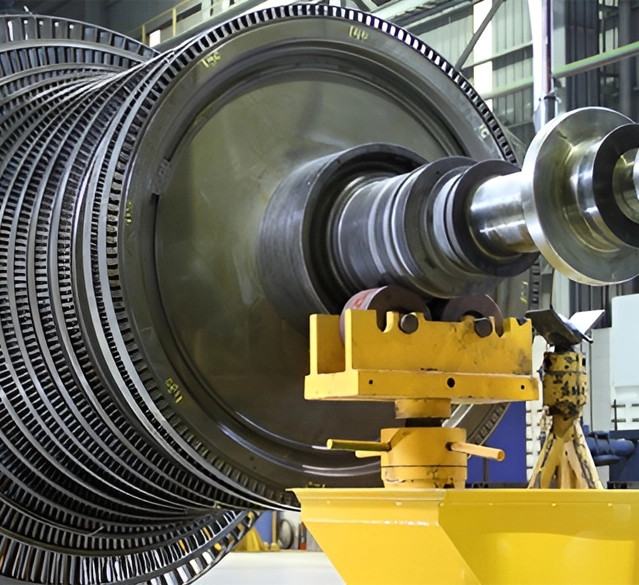

LubeAdd® Ashless Turbine Oil Additives are high-performance additive package designed to enhance the efficiency, durability, and oxidation stability of turbine oils. This advanced ashless formulation provides exceptional deposit control, wear protection, and anti-foaming properties, ensuring smooth and reliable turbine operation across industrial and power generation applications.

LubeAdd® Ashless Turbine Oil Additives ensures long-lasting, high-performance lubrication, making it ideal for gas, steam, and hydraulic turbines operating under extreme conditions.

LubeAdd® Neat Cutting Oil Additives are specialized formulation designed to enhance the performance of cutting oils in precision machining applications, particularly in nut forming, bolt forming, and similar processes. This additive optimizes the lubrication and cooling properties of cutting fluids, ensuring smooth operation and extending tool life.

With LubeAdd® Neat Cutting Oil Additives, you can enhance the performance of your cutting oils, ensuring optimal machining efficiency and superior surface quality in your operations.

LubeAdd® Gear Oil Additive Packages are specifically designed to enhance the performance of gear oils, making it suitable for formulating high-performance lubricants across various SAE grades.

With the LubeAdd® Gear Oil Additive Packages, you can achieve superior performance and protection in both automotive and industrial gear applications, ensuring smooth operation and reliability in demanding environments.